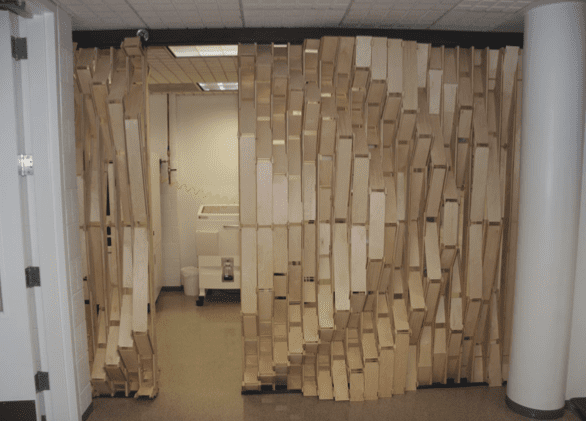

Ripple Wall

DIGITAL FABRICATION LAB WALL

Created as an installation and competition entry (see page 71), this project was constructed to demonstrate a system tied to the parameters of both material and machine. The system used no mechanical or adhesive connections, employing only the precision of a 2.5 axis CNC router to define built-in connection details. The intent of the project was to provide a demonstration of the accuracy, which CNC tooling is capable of providing, and as a map of the machine’s parameters.

The original surface is a rippling form constrained to 18” of total thickness and approximately 8’ X 14’ of wall space. The 18” thickness was developed from a series of analytical mockups, which determined that a 9” cantilever in .75” square sections of plywood held up appropriately. The cantilevers hold .25” thick panels out each side of the surface creating 18” of total thickness. The ripple form was derived from the necessity to “flip” back and forth through the structural center of the composition, so that the members never became too long, and so that the panels were able to take advantage of the larger surface area for connection to their center posts.

The .25” CNC router bit defines the connection for this system. Each panel is held in place with a friction fit depth cut or insert, the length of each panel. The panels are cut from .25” birch veneer plywood and nest cleanly into the .25” cut width. The structural ribs or “trunks” are cut from .75” birch- veneer plywood. To minimize material waste, we separated the cantilevered “branch” components from each structural member. Each of these separated components slot into the vertical using a puzzle piece connection.This connection slot defines the angle of connection and uses the minimum size puzzle piece cut that a .25” diameter router bit can perform.